Who we are and what is our mission

We are Benson Signs, one of the largest manufacturers of signage in the UK. We provide signage to companies large & small across the whole of the UK and were established in 1969.

Some of our Clients

Client Testimonials

Don’t take our word for it – here’s what our clients say:

We have had continuously good service from the team at Bensons.

National Museums Liverpool

You always go the extra mile for us especially when we come through with very late deadlines and last minute requests.

Tate, Liverpool

Benson’s are very good to work with. They always put the customer first and strive to provide the best service 100% of the time.

Costa Coffee

Particularly pleased with the response time from initial contact to providing drawings, to the manufacture of the signs. We look forward to working with you again.

Liverpool Womens NHS Foundation Trust

Everyone I dealt with, from the quotation request to the installation, was very helpful. I have already passed on your details to another school as I would have no hesitation working with you again.

Cardinal Heenan, Catholic High School

Cannot fault in any way. Excellent service from start to finish.

Riverside Bowl and Laser Quest

What services we offer

Design Service

Our design team can produce sign project visuals, original artwork, proposed elevations, photo montages and technical illustrations of one off signs or full signage projects.

Consultancy & Project Management

With our wealth of experience we are able to advise you on the best solution including materials and longevity for any sign project, large or small, from design through to completion and tailor it to suit client’s requirements, timescales and your individual budget.

Installation & Maintenance

Our experienced installation teams are IPAF and PASMA trained and hold CSCS cards. We offer a nationwide sign installation and maintenance service with regular or one-off visits to help prolong the life span of your signage.

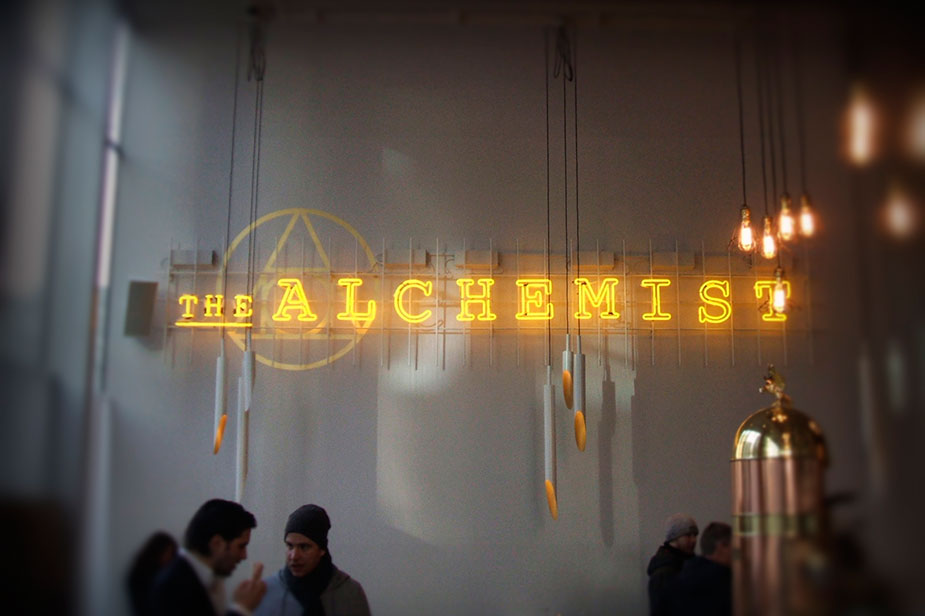

Photo gallery

- The Alchemist – Manchester

- Costa Coffee Drive Thru – Crewe

- Holland and Barrett – Leicester

- Pizza Hut – St.Helens

- Sigma Sports Signage

- Manufacturing Subway Signage

- Wondrous Place Gallery – Liverpool Museum

- YMCE Halo Illuminated Signage

- Albumedix – Nottingham